COMPANY

COMPANY PROFILE

BNTET Renewable Energy Equipment is a new energy-saving and high-efficiency device jointly developed by "Reke Energy Company" and Henan Polytechnic University. Its core components are independently researched, designed, and manufactured.

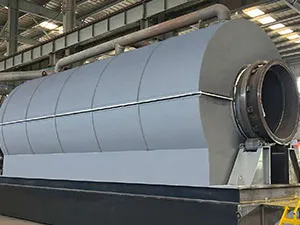

Main products include: Pyrolysis plant, cracking furnaces, gasification furnaces, carbonization furnaces, incinerators, burners, heat exchangers, oil condensation recovery systems, and auxiliary equipment.

The R&D team consists of 15 members, primarily composed of professors, PhDs, and experts. Core members:

Wen Xiaoping: Professor, Ph.D., Ph.D. Supervisor. Member of the International Combustion Institute. Published over 40 papers in renowned domestic and international journals such as Fuel, International Journal of Hydrogen Energy, Journal of Thermal Science, CIESC Journal, and Journal of China Coal Society, with over 20 SCI/EI-indexed papers. Authored 3 textbooks and academic monographs, and holds over 30 national patents.

Chen Guoyan: Postdoctoral researcher, Senior Engineer, Master's Supervisor. Ph.D. in Combustion Science from Tsinghua University, Visiting Scholar at Western Kentucky University, USA. Published 30 papers in prestigious journals including Proceedings of the CSEE and Fuel, with 15 SCI/EI-indexed papers. Filed and granted 15 national patents.

Deng Haoxin: Ph.D., Lecturer, Master's Supervisor. Graduated from the Institute of Engineering Thermophysics, Chinese Academy of Sciences. Published over 40 papers in journals such as Fuel, Journal of Thermal Science, CIESC Journal, and Journal of China Coal Society, with 30+ SCI-indexed papers. Recognized in academia as "a walking encyclopedia of combustion science."

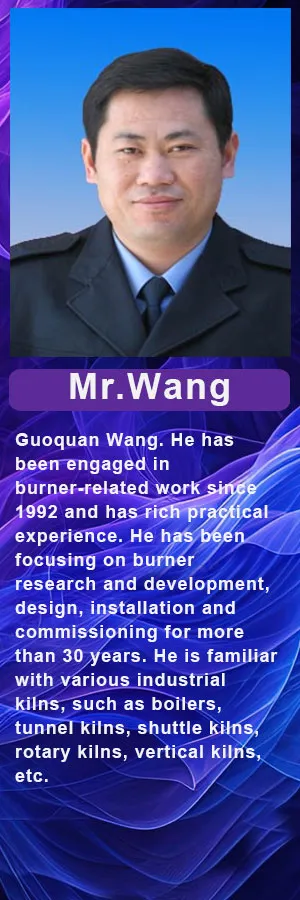

Wang Guoquan: Graduated from Wuhan Institute of Technology with a major in Thermal Energy Engineering. Engaged in burner-related work since 1992, specializing in burner R&D, design, installation, and commissioning for over 30 years. Expert in industrial kilns such as boilers, pyrolysis furnaces, cracking furnaces, gasifiers, carbonization furnaces, incinerators, and tunnel kilns.

BNTET boasts a robust R&D team. Prior to production, professors conduct 1:1 numerical simulation thermal analysis for each device. Through multi-field simulations (cold/hot-state flow fields, temperature fields, component fields), furnace structures and burner designs are optimized to achieve superior theoretical performance.

With 15 years of experience in burner design and production—the core component of pyrolysis furnaces—BNTET prioritizes combustion efficiency and stability. Tailored for pyrolysis plant, BNTET's dedicated burners save over 10% energy compared to conventional models, deliver optimal air-fuel ratios, reduce costs, and ensure safety, efficiency, and environmental compliance.

Backed by cutting-edge theoretical expertise, decades of practical experience, and a customer-first philosophy, BNTET looks forward to collaborating with you for mutual success!

PRODUCTS DISPLAY

PROJECT

OUR PRODUCT

Biomass Gasifier · Pyrolysis Plant ·Charcoal Making Machine

PRODUCT APPLICATION

●Plastic Recycling Industry ●Tyre Recycling Industry ●Oil Sludge Treatment ●Waste To Oil ●Waste To Gas ● Food-processing Industry ●Palm Cultivation And Palm Oil Industry ●Agricultural Planting Industry ●Carbon Removal Industry

Certificates