What role does the condenser play when pyrolyzing tires

2025-02-21 10:53:13

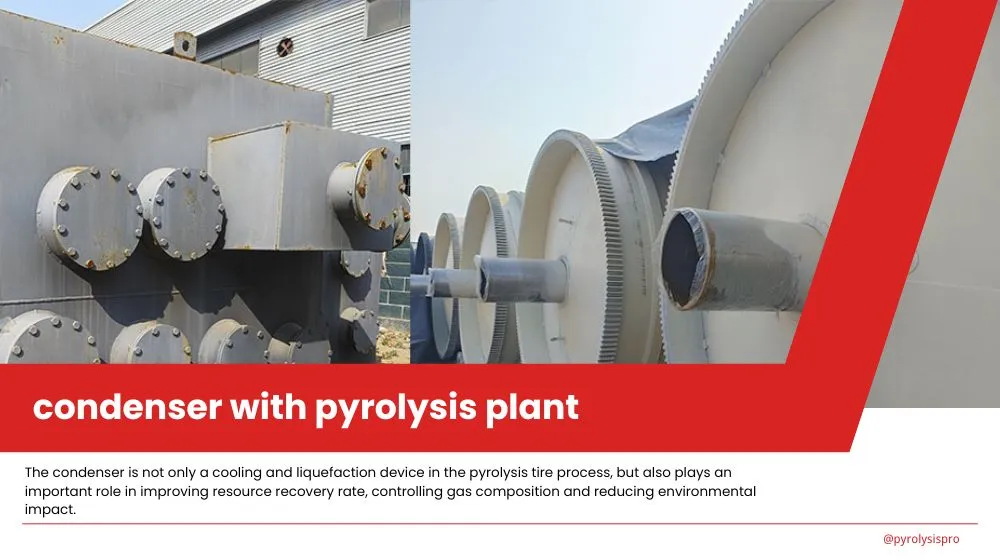

In the tire pyrolysis process, the condenser plays a key role, which is mainly reflected in the following aspects:

1. Gas cooling and liquefaction

When pyrolyzing tires, the tires decompose at high temperatures and produce gases (such as volatile organic compounds, oil and gas, etc.). The main function of the condenser is to cool these high-temperature gases so that they can be liquefied to form liquid oil and other recoverable chemicals.

2. Improve recovery efficiency

Through the condensation process, the condenser can effectively recover valuable liquid products (such as tire oil and carbon black) produced during the pyrolysis process, improving the overall material recovery rate. These liquids can be further processed or directly used for energy production.

3. Control gas composition

The condenser can separate gas components with different boiling points to help extract specific chemicals. For example, heavier oil and gas will be cooled and liquefied first in the condenser, while light gases may continue to flow to downstream processing equipment.

4. Reduce environmental pollution

By effectively condensing and recovering harmful gases, the condenser can reduce pollution to the environment, reduce the emission of harmful gases, and meet environmental protection requirements.

5. Energy saving

The use of condensers can recycle the heat energy released during the pyrolysis process, and part of the heat energy can be reused, thereby improving the energy efficiency of the entire pyrolysis system.

Summary

The condenser is not only a cooling and liquefaction device in the pyrolysis tire process, but also plays an important role in improving resource recovery rate, controlling gas composition and reducing environmental impact. Through an effective condensation process, various products produced during the pyrolysis process can be maximized, contributing to sustainable development.