Continuous Carbonization Furnace

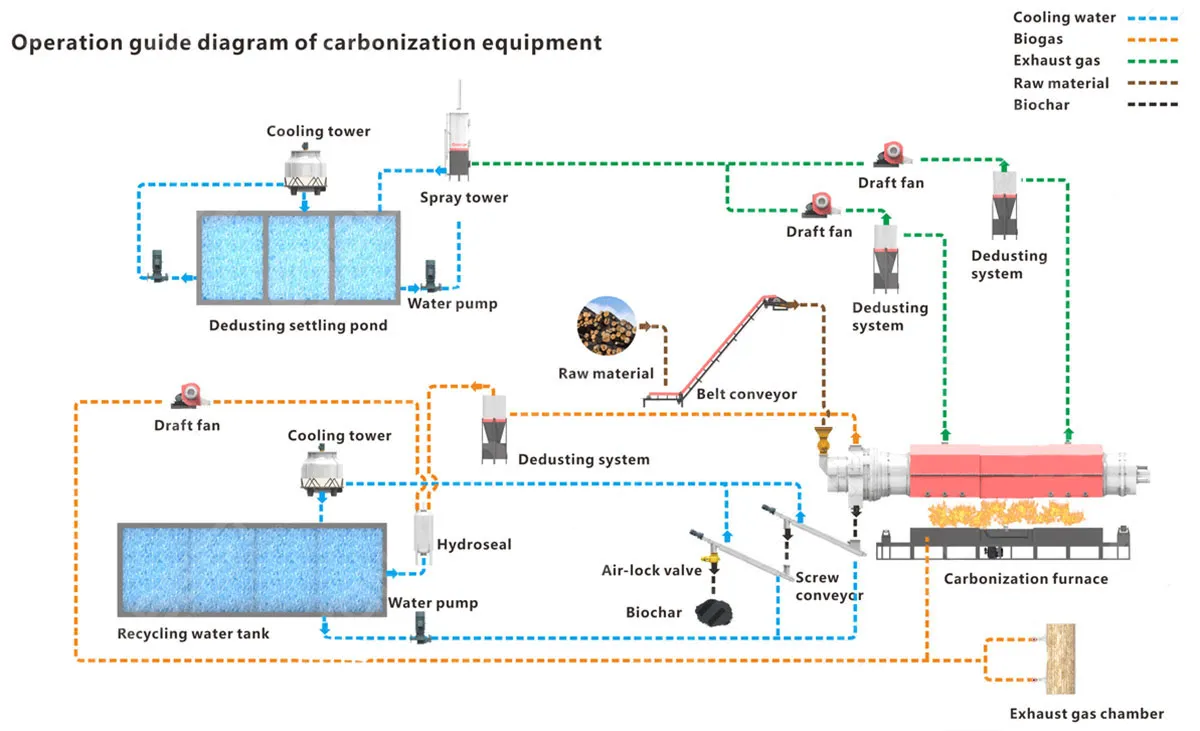

A Biomass Continuous Carbonization Furnace is a device that heats and decomposes biomass raw materials (such as wood, straw, fruit shells, etc.) under oxygen-deficient or oxygen-limited conditions to

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

Question 1-Product Description

A Biomass Continuous Carbonization Furnace is a device that heats and decomposes biomass raw materials (such as wood, straw, fruit shells, etc.) under oxygen-deficient or oxygen-limited conditions to produce biomass charcoal, combustible gas and by-products.

Question 2-Product Parameter

| Model | BN-BCF-05 | BN-BCF-08 | BN-BCF-10 | BN-BCF-12 | BN-BCF-14 |

| Capacity/H | 0.4-0.7m³/H | 2-5m³/H | 7-9m³/H | 10-13m³/H | 13-17m³/H |

| Working | Continuous | ||||

| Raw Materials | 1. All kinds of biomass waste, such as sawdust, Coconut shells, olive shells, palm hells, bamboo,etc. 2. Civil sludge, municipal sludge, industrial sludge,etc 3. MSW | ||||

| Reactor Size | Φ500 | Φ800 | Φ1000 | Φ1200 | Φ1400 |

| Construction | Double cylinder double sealed single furnace | ||||

| Heating | Diesel, Natural Gas, LPG, Biomass, etc. | ||||

| Total Power | 26kw | 40kw | 55kw | 60kw | 72kw |

| Area(L*W*H) | 25m*15m*6m | 30m*15m*7m | 35m*15m*7m | 45m*15m*10m | 50m*15m*10m |

| Pressure | Slightly negative pressure | ||||

| Cooling | Recycling Water Cooling | ||||

| Noise | ≤70dB | ||||

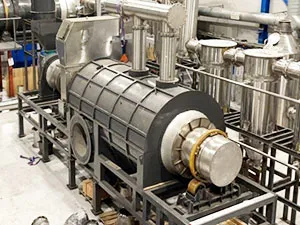

Question 3-Product Display

Features of biomass carbonization furnace

1. Small footprint: It adopts horizontal double-barrel carbonization treatment technology, which has the advantages of fast processing speed, short processing cycle, large equipment processing capacity, and small footprint.

2. Low energy consumption: In normal production, the combustible gas generated by the carbonization process is used as fuel, which greatly reduces the energy consumption cost. The heating furnace adopts a closed combustion chamber, which has high heating efficiency; there are insulation measures inside to effectively reduce heat loss.

3. Safe and reliable: The whole machine adopts an integrated seal (feeding, carbon discharge, and combustible gas outlet are at the same end) and 6 sealing processes. Compared with the large long-barrel carbonization equipment that requires sealing at both ends, we only have the front end seal, which reduces one leakage point and improves production safety.

4. Convenient transportation and installation: The overall carbonization system adopts a modular design, which is convenient for transportation, assembly, maintenance and maintenance.

Continuous-Carbonization-Furnace04

Continuous-Carbonization-Furnace06

Question 4-Application

Question 5-FAQ

Q: What raw materials are suitable for continuous carbonization furnaces?

A: Continuous carbonization furnaces can process a variety of biomass raw materials, including:

●Wood (wood chips, wood blocks, branches, etc.)

●Agricultural waste (straw, rice husks, corn cobs, etc.)

●Fruit shells (coconut shells, walnut shells, etc.)

●Other organic waste (such as sludge, domestic garbage, etc.).

Q:What are the byproducts produced during the carbonization process?

A:The following byproducts are produced during the carbonization process:

●Combustible gas: can be used to heat the carbonization furnace or generate electricity.

●Tar: can be collected and used as chemical raw materials.

●Wood vinegar: can be used in agriculture or industry.

Q: Does the operation of the equipment require special personnel to operate?

A:Continuous carbonization furnaces are usually highly automated and only require a small number of personnel to monitor the operating status. However, the operators need to be trained and familiar with the equipment operation and maintenance procedures.

Question 6-Our service

Hot Tags: Charcoal Making Machine,Continuous Carbonization Furnace

none

none