Plastic pyrolysis plant

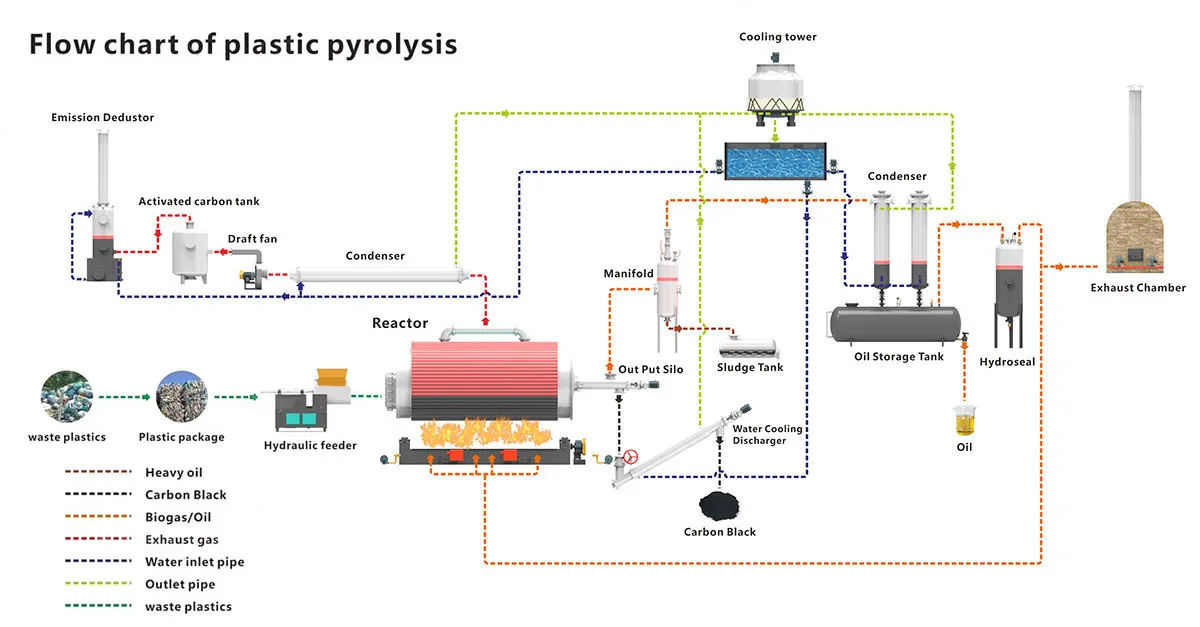

A plastics pyrolysis plant is a device used to convert waste plastics into fuel oil, gas and solid residues (e.g. carbon black) by thermal cracking technology.

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

Question 1-Product Description

The Plastics Pyrolysis Plant is a state-of-the-art recycling facility that utilizes high temperature pyrolysis technology to convert waste plastics into a variety of high-value products such as fuel oil, carbon black and combustible gases.

The plant is capable of processing many types of plastic waste, including polyethylene (PE), polypropylene (PP) and polystyrene (PS). Whether it is packaging materials, plastic bottles, plastic bags, or other plastic products, they can all be resourcefully recycled through pyrolysis technology.

This process not only effectively reduces the environmental pollution caused by plastic waste, but also converts the waste into reusable energy and industrial raw materials, which has significant environmental and economic value.

Question 2-Product Parameter

| Model | BN-PR-3 | BN-PR-6 | BN-PR-10 | BN-PR-15 |

| Processing capacity | 3T | 6T | 10T | 15T |

| Reactor size(mm) | 1500*3500 | 2400*5000 | 2600*6600 | 2800*8000 |

| Pyrolysis time(h) | 3-4 | 4-6 | 6-8 | 8-10 |

| Feeding time(h) | 0.5 | 0.7 | 1 | 1 |

| Cooling time(h) | 3-4 | 4-5 | 4-5 | 5-6 |

| Discharging time(h) | 0.5 | 0.7 | 1 | 1 |

| Power needed(kw) | 12.5 | 18.6 | 32.5 | 35.5 |

| Water consumption(kg) | 100 | 300 | 500 | 500 |

| Fuel consumption(kg/h) | 30 | 40 | 60 | 90 |

| Area covered(W*L)m² | 2.3*11.5 | 8*22 | 8*30 | 8*30 |

| Application initial heating fuel | Natural gas/LPG/Diesel/Pyrolysis oil | |||

| Noise(dB) | ≤80dB | |||

| Working process | Batch type | |||

| Cooling method | Water cooling | |||

Question 3-Product Display

PRODUCT BENEFITS

☆☆☆☆☆

1. Resource utilization

Convert waste plastics into valuable fuels and chemicals.

2.Pollution Reduction

Reduces the environmental harm caused by plastic waste, especially pollution of soil and sea.

3.Energy recovery

The oil and gas produced by cracking can be used as energy.

pyrolysis-plant-details-1

pyrolysis-plant-details-3

Question 4-Application

Question 5-FAQ

Q:What is the difference between tire pyrolysis plant and plastic pyrolysis plant?

A:Plastic pyrolysis plant can be used to crack tires, but tire pyrolysis plant cannot be used to crack plastics.

Q:How long is the warranty?

A:One year, but we provide lifelong technical service and free software system upgrade.

More info....

Question 6-Our service

Hot Tags: Plastic pyrolysis plant,pyrolysis plant

none

none